Liquid Flexo Printing

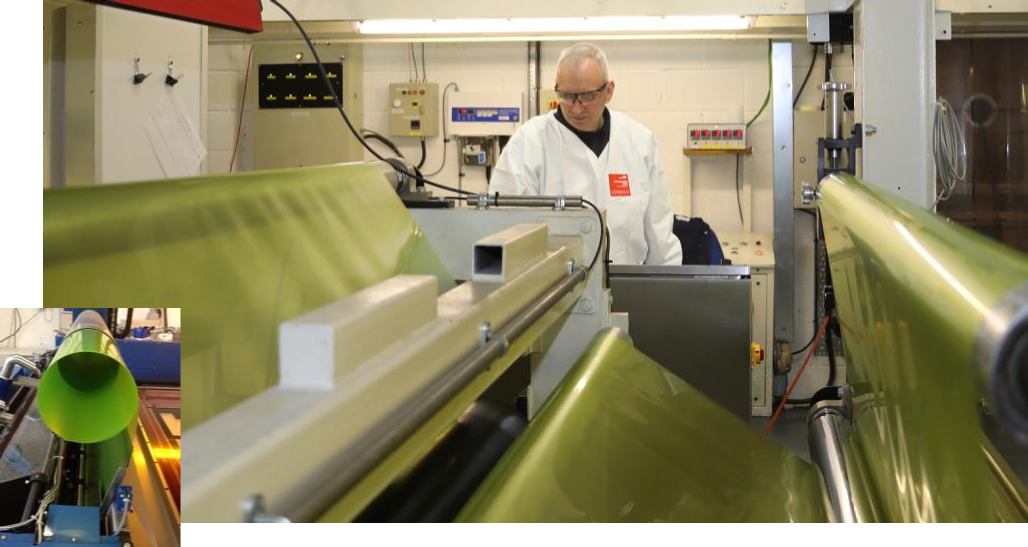

DEP supply a number of products to meet the demands of the Liquid Flexographic platemaker and works with customers to modify our formulations to meet specific market demands.

By using years of expertise in clean room coated adhesives and surface bond coatings DEP is able to supply Base Films and specialized adhesive coated products for the liquid flexographic market.

Our specially formulated coating onto polyester ensures maximum adhesion to commercially available photo-polymer resins

DEP’s Photopolymer base films are highly stable polyester backing sheet materials that are regularly used by Liquid Flexo plate makers across the globe. The specially formulated coating onto polyester ensures maximum adhesion to commercially available photo-polymer resins.

DEP’s Photopolymer base films are highly stable polyester backing sheet materials that are regularly used by Liquid Flexo plate makers across the globe. The specially formulated coating onto polyester ensures maximum adhesion to commercially available photo-polymer resins. A one side matt 20micron film specially formulated for protective cover of Flexo negatives during photopolymer exposure. Easily strips away after exposure.

A one side matt 20micron film specially formulated for protective cover of Flexo negatives during photopolymer exposure. Easily strips away after exposure. DEP has unique products with a special adhesive layer on the reverse side of the base film which allows for easy mounting of the finished Flexo plate onto Plate Carrier material.

DEP has unique products with a special adhesive layer on the reverse side of the base film which allows for easy mounting of the finished Flexo plate onto Plate Carrier material.